Description

Hot-melt Case Sealer – Overview

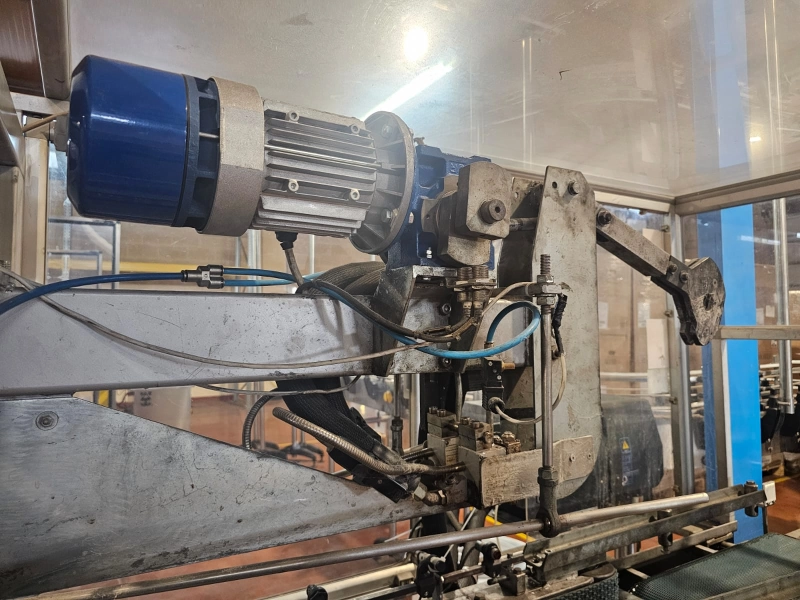

This used hot-melt case sealer by TE-CO is engineered for end-of-line industrial packaging within a used bottling line. The model 607-98 provides reliable, consistent closure of corrugated cartons using a hot-melt adhesive system, making it a proven solution for beverage production environments where wine bottles in cases must be sealed securely prior to palletizing. With robust construction and straightforward operation, it integrates seamlessly with upstream case packers and downstream palletizers to support continuous operation and optimized throughput.

Manufactured by TE-CO, this second hand unit focuses on dependable carton closure, ensuring clean glue application, tight seals, and minimal maintenance demands. It is especially suitable for cases containing glass bottles in common formats used by wineries and beverage producers. Designed to work as part of a complete used bottling line or as a stand-alone machine with compatible conveyors, the 607-98 aligns with industrial packaging best practices for efficiency and product protection.

Technical Specifications & Performance Data

- Manufacturer: TE-CO

- Model: 607-98

- Year of manufacture: 1998

- Sealing method: Hot-melt (glue) adhesive

- Application: Case/carton sealing after case packing

- Typical use: Wine bottle cases within a used bottling line

- Compatible bottle formats in cases: 0.75L, 1.0L, 1.5L

- Construction: Industrial end-of-line machine for continuous operation

- Operation: Inline with case packer upstream and palletizer downstream

Advanced Automation & Control Systems

The TE-CO hot-melt case sealer is designed for dependable automation in industrial packaging. Typical features include adhesive temperature control for consistent bonding, synchronized infeed and outfeed for smooth case flow, and safety interlocks for protected operation. Operator-friendly controls support quick adjustments and stable performance during format changes. The hot-melt application system helps deliver clean, repeatable glue patterns to ensure secure, uniform sealing.

Production Line Integration Capabilities

This case sealer integrates naturally into a used bottling line, operating immediately after a case-packing monoblock and before palletizing. It can be synchronized with upstream equipment such as erecting and packing systems and connected downstream to palletizers for automated material handling. The machine supports inline operation with standard conveyors and can run as a stand-alone sealer when properly fed.

Machine Condition & Maintenance History

The machine is presented as ready for operation within a second hand used bottling line context. Safety features and documentation are available, supporting commissioning and routine maintenance. Its industrial build promotes reliable service in beverage production environments.

Operational Performance & Versatility

Optimized for sealing cartons that contain glass bottles, this TE-CO 607-98 suits wineries and beverage producers requiring secure hot-melt closure. The adhesive system promotes precise application for strong, clean seals. The design supports efficient end-of-line flow, helping maintain product integrity through transport and storage.

Installation Requirements & Site Preparation

The sealer is intended for installation on a level production floor with appropriate conveyor interfaces. Utilities typically include electrical power suitable for hot-melt adhesive systems and controls. Adequate clearance for operator access and maintenance is recommended, along with integration to upstream and downstream equipment for continuous operation.

Safety Standards & Compliance Certification

Safety guarding, interlocked access points, and emergency stop circuits support operator protection and safe operation. The machine design aligns with industrial packaging safety practices, suitable for beverage and wine bottling applications requiring hygienic, reliable end-of-line sealing.