Description

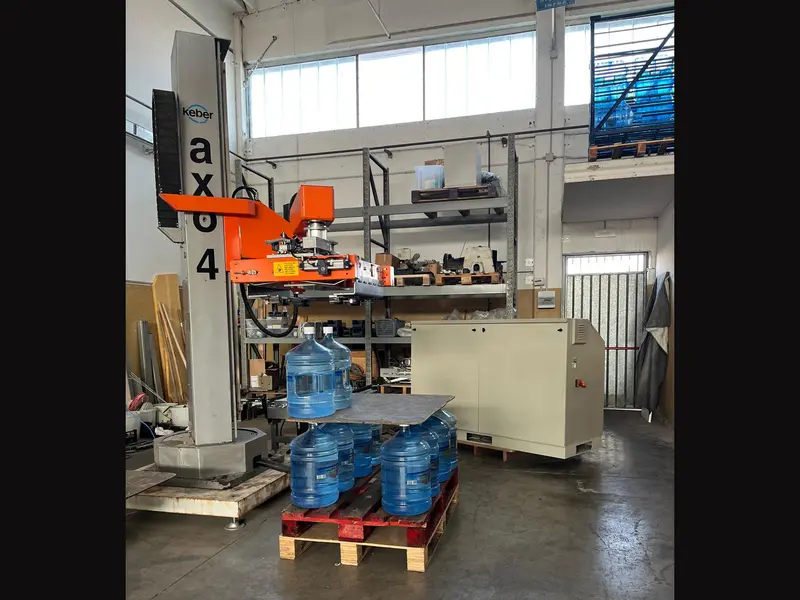

Used Keber PALPACK DS Palletizer

The Keber PALPACK DS is a conventional automatic palletizer designed for end-of-line carton palletizing in beverage production and industrial packaging environments. This secondhand solution streamlines the final stage of a used bottling line by arranging sealed cartons into stable layers and placing them onto pallets according to predefined stacking patterns. Engineered for reliable throughput and smooth handling, it helps producers prepare loads for wrapping, storage, and transport with consistent quality and minimal operator intervention.

Manufactured by Keber, the PALPACK DS integrates seamlessly into complete packaging lines processing glass bottles packed in cartons. Typical applications include bottled beverages in standard retail formats such as 0.75L, 1.0L, and 1.5L. Its practical layout and robust construction support continuous-duty operation in demanding facilities where uptime and pallet stability are essential. Whether upgrading an existing used bottling line or expanding capacity, this palletizing system offers dependable performance in a compact, operator-friendly footprint.

Technical Specifications & Performance Data

- Manufacturer: Keber

- Model: PALPACK DS

- Machine type: Conventional automatic palletizer for cartons

- Year: 2004

- Container handling: Designed for glass bottles packed in cartons

- Bottle formats: Compatible with 0.75L, 1.0L, 1.5L bottle formats (cartonized)

- Pallet format: Eur-Epal pallet, 800×1200 mm

Advanced Automation & Control Systems

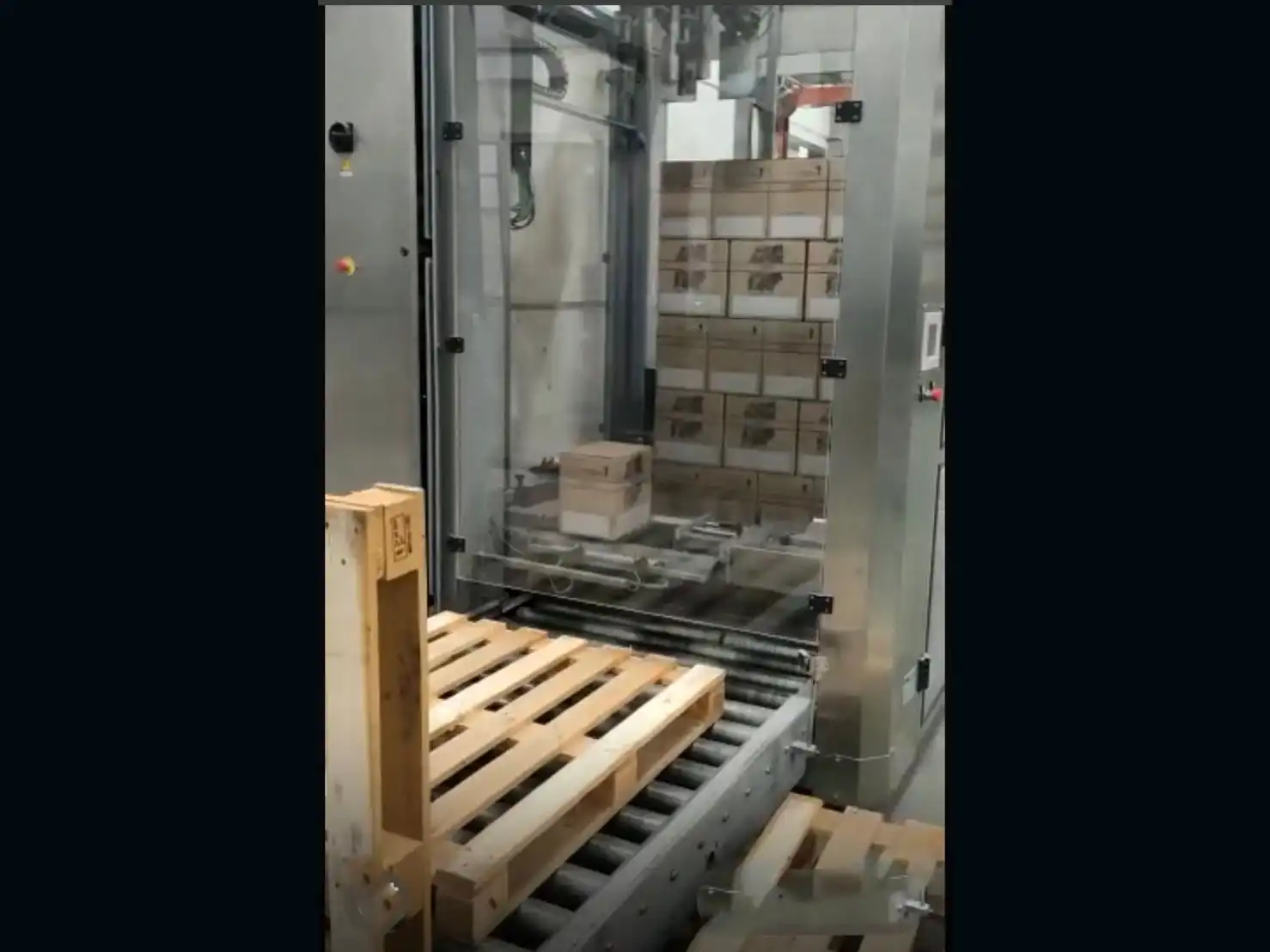

The PALPACK DS enables automated layer forming and orderly pallet build-up for consistent, repeatable results. Its end-of-line control logic coordinates carton infeed, layer positioning, and pallet changeover, helping operators maintain stable stacks for downstream wrapping. The design supports clear operator access, safety interlocks, and straightforward adjustments to maintain efficiency during product runs and format changes.

Production Line Integration Capabilities

This palletizer is positioned downstream of a hot-melt case sealing stage and upstream of pallet wrapping, enabling a continuous, automated flow from packed case to finished pallet. It is compatible with standard conveyor systems and integrates into used bottling line layouts handling glass bottle cartons. The system is suited to beverage production where multiple bottle sizes are packed into cases and prepared for distribution.

Typical integration examples include:

- Upstream: hot-melt case sealer (e.g., TE-CO 607-98)

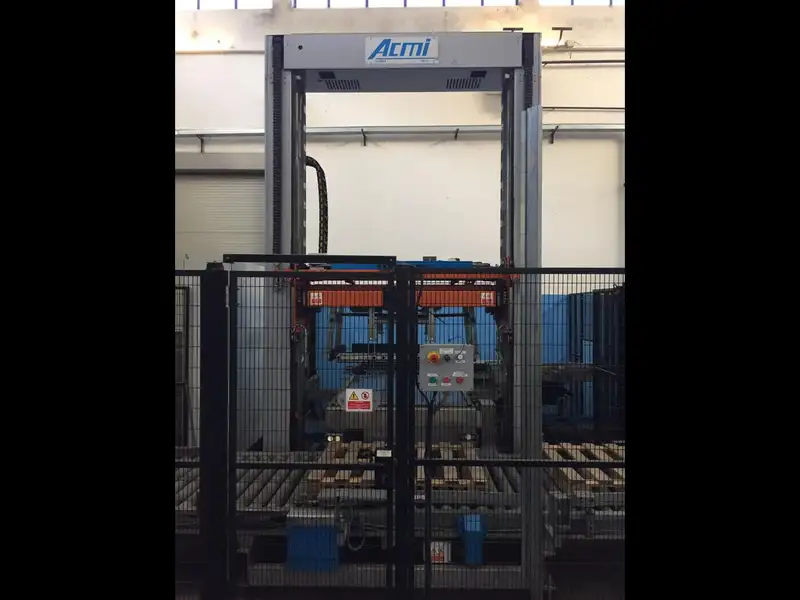

- Downstream: automatic pallet wrapper (e.g., Imballaggi Service Group EASY WRAP 2000 A)

Machine Condition & Maintenance History

This equipment is listed as ready for operation within a complete line context. It is presented as a functional, secondhand palletizer suitable for immediate integration into industrial packaging and beverage production workflows.

Operational Performance & Versatility

The PALPACK DS focuses on carton palletizing for glass bottle packaging, supporting stable, repeatable pallet loads that protect product quality during handling and transport. Its design emphasizes consistent layer formation, dependable transfer to pallets, and compatibility with common pallet wrapping systems to ensure finished loads meet logistics requirements.

Installation Requirements & Site Preparation

The palletizer is intended for installation at the end of a production or packing line with appropriate conveyor interfaces. A level floor, adequate clearance for pallet handling equipment, and access for maintenance are recommended. Utilities typically include electrical power and, where applicable, compressed air for actuated devices and ancillary functions.

Safety Standards & Compliance Certification

The system is designed with operator safety in mind, typically incorporating perimeter guarding, interlocked access points, and emergency stop circuits in line with common industrial packaging practices. The palletizing process supports hygienic handling of secondary packaging for beverage production where cleanliness, reliability, and load integrity are critical.