Description

Technical Specifications & Performance Data

This automatic labeling machine is engineered for precise application of multiple labels and capsule handling in beverage production environments. It features three self-adhesive labeling stations configured for front, back, and neck ring label or DOCG tax stamp application, making it ideal for wineries and premium beverage brands. The system integrates a capsule distributor with magazine and a roller spinner for consistent capsule application. A motorized conveyor with a dedicated positioning platform ensures accurate bottle handling and repeatable label placement.

- Labeling technology: Self-adhesive (pressure-sensitive) with 3 stations

- Label placements: Front, back, and neck ring label or DOCG tax stamp

- Capsule handling: Capsule distributor with magazine and roller spinner for capsule application

- Conveyor: Motorized conveyor equipped with positioning platform

- Operation mode: Linear bottle transport

- Container compatibility: Designed for Glass bottle handling, especially cylindrical wine bottles

- Use case: Suitable for integration into a used bottling line or second hand industrial packaging projects

Advanced Automation & Control Systems

The machine supports modern automation practices for stable, repeatable labeling quality. Bottle presence detection, label web management, and synchronized applicator control contribute to high uptime and reduced waste. Operator interaction is simplified through accessible controls and standardized settings for each labeling station.

- Coordinated control of multiple adhesive stations for synchronized front/back application

- Positioning platform on the conveyor for accurate label placement

- Support for quick format setup across stations

- Safety interlocks on moving areas and standardized operator controls

Production Line Integration Capabilities

Designed to integrate seamlessly into existing bottling equipment and packaging machinery, the machine can operate as a standalone labeling module or inline within a complete production line. It is an excellent fit for beverage production environments that require coordinated capsule application and multi-panel labeling.

- Inline or standalone operation with upstream/downstream conveyors

- Compatible with fillers, cappers, and other equipment in a production line

- Efficient changeover between label sets and bottle designs

- Ideal for bottling line upgrades and line expansions

Machine Condition & Maintenance History

Self-adhesive labeling systems are known for clean operation and reduced maintenance compared to glue-based technologies. Routine preventive maintenance on the label unwind/rewind, rollers, and capsule distributor ensures reliable performance and consistent application quality over time.

- Low-maintenance, clean adhesive technology

- Service-friendly access to labeling heads and capsule module

- Suitable for refurbishment and recommissioning within industrial packaging environments

Operational Performance & Versatility

The configuration supports premium presentation requirements with synchronized front/back labeling and optional neck ring or DOCG tax stamp placement. The integrated capsule distributor with magazine and roller spinner enables a compact capsule application solution on the same line, streamlining operations and improving throughput.

- High-quality front/back label alignment for premium branding

- Optional neck ring or DOCG tax stamp application for regulatory and aesthetic needs

- Capsule distribution and rolling for wine presentation standards

- Consistent results on Glass bottles used in beverage production

Installation Requirements & Site Preparation

The linear layout simplifies placement within existing production spaces. Site preparation typically includes stable flooring, adequate power supply, and provision for compressed air as required by the applicators and capsule module.

- Linear footprint suitable for integration into existing lines

- Power and compressed air services as per configuration

- Clear access for operator loading of labels and capsule magazine

- Ambient conditions suitable for adhesive label application

Safety Standards & Compliance Certification

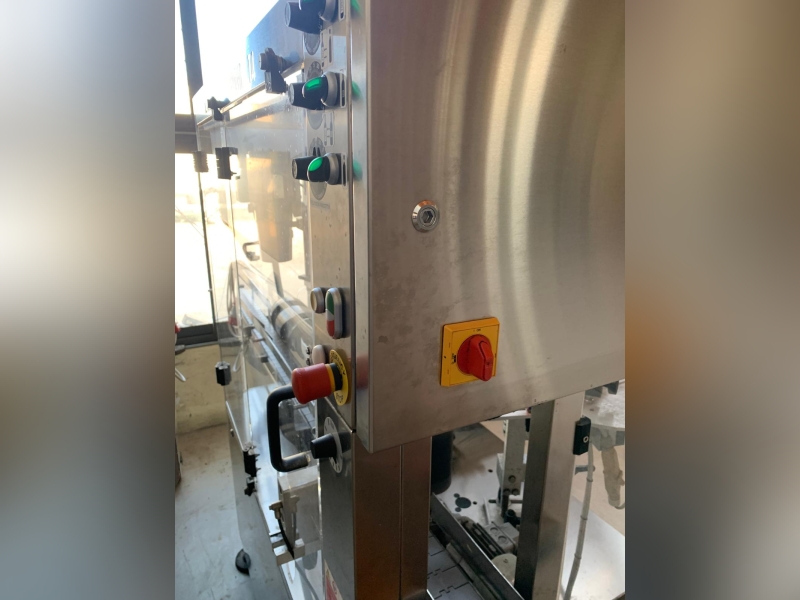

The machine incorporates operator safety measures in line with common industrial practices for bottling equipment. Guarding and emergency stops help protect personnel while enabling efficient operation and maintenance.

- Guarded moving parts around applicators and conveyor

- Emergency stop pushbuttons at accessible locations

- Interlocked doors on critical zones for safe operation

- Hygiene-oriented design suitable for beverage applications