Description

Technical Specifications & Performance Data

This Rinsing-Filling-Capping Triblock by FIMER is a robust rotary monoblock engineered for glass bottle handling and precision filling. Built on the model SRT 24-24-6, it integrates a 24-clamp rinser with mobile nozzle, a 24-valve gravity/light depression filler, and a 6-head aluminum screw capper. Designed for reliable operation in beverage production and industrial packaging, it is suitable for second hand and used bottling line upgrades where consistent performance and compact footprint are priorities.

- Manufacturer: FIMER

- Model: SRT 24-24-6

- Year: 1998

- Rinser: 24 grippers, mobile nozzle

- Filler: 24 valves, gravity/light depression (slight vacuum)

- Capper: 6 heads, aluminum screw caps 31,5 x 18

- Cap handling: Complete with cap elevator

- Electrical power: 6.5 kW

- Power supply: 380 V, 50 Hz

- Compressed air: Max 6 bar

- Construction: Rotary triblock for glass bottles

Advanced Automation & Control Systems

The triblock integrates coordinated rotary turrets for synchronized rinsing, filling, and capping. It is designed for straightforward operation with clear machine status visibility and quick access to critical areas for adjustments. The filler operates on gravity/light depression principles for stable liquid level control, ideal for products like vinegar in glass bottles.

- Electrical configuration: 380 V, 50 Hz

- Installed power: 6.5 kW

- Filling technology: Gravity/light depression for accurate, low-turbulence filling

- Safety systems: CE-marked with protective guarding and emergency stop circuits

- Changeover: Format changes supported via standard change parts

Production Line Integration Capabilities

This unit can be integrated into a complete used bottling line or operate as a standalone monoblock in glass bottling applications. It interfaces easily with upstream bottle conveyors and downstream inspection, labeling, and packaging machinery in beverage production and industrial packaging environments.

- Operation mode: Inline integration or standalone

- Container handling: Designed for glass bottles

- Cap logistics: Integrated cap elevator for continuous feeding

- Applications: Suitable for vinegar and similar still products

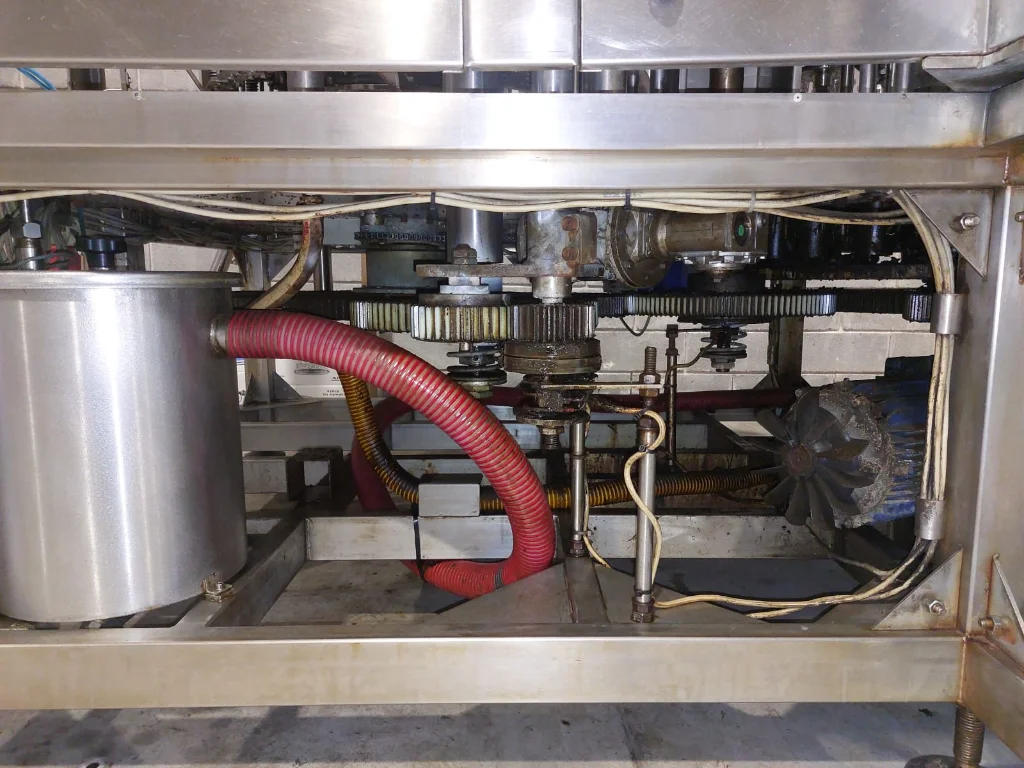

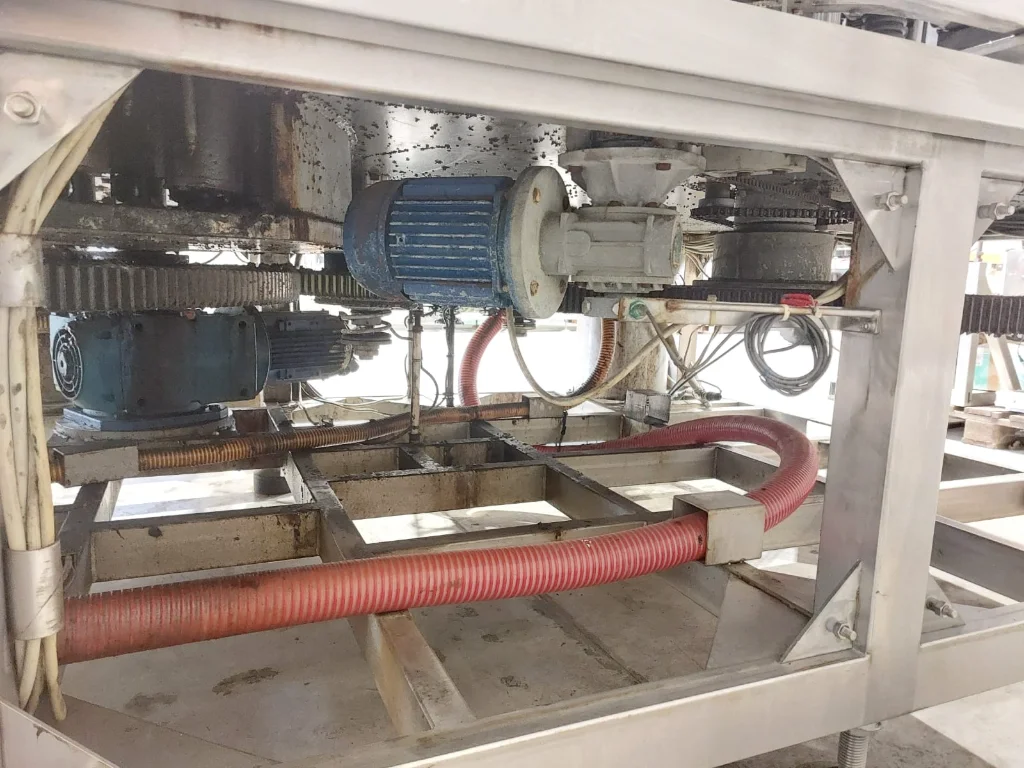

Machine Condition & Maintenance History

The triblock comes from a professional bottling context and is presented as a second hand solution in working condition, ready for operation. The configuration and components indicate routine industrial use with standard maintenance practices typical of glass bottling environments.

- Status: Ready for operation

- Usage: Previously used to fill vinegar into glass bottles

Operational Performance & Versatility

With 24 rinsing grippers and 24 filling valves, the machine provides balanced throughput, while the 6-head capper ensures consistent aluminum screw cap application. The light depression filling system supports clean filling of still, low-foam products with precise level control.

- Product types: Still liquids; historically used for vinegar

- Cap types: Aluminum screw, 31,5 x 18

- Quality control: Stable filling process with gentle product handling

Installation Requirements & Site Preparation

Installation requires standard utilities and a level foundation. The rotary triblock layout optimizes footprint while enabling accessible maintenance and sanitation.

- Utilities: 380 V 50 Hz electrical supply; compressed air up to 6 bar

- Integration: Connects to standard conveyor systems for bottle infeed/outfeed

- Sanitation: Accessible for cleaning and routine maintenance

Safety Standards & Compliance Certification

The machine complies with key industrial safety requirements and is CE-marked. Protective guards, interlocks, and emergency stop functions support operator safety and hygiene standards suitable for food-grade bottling operations.

- Compliance: CE-marked

- Operator protection: Safety guarding and emergency stops

- Hygiene: Designed for food and beverage-grade cleaning practices