Description

Used Cap Applicator – Overview

This used cap applicator, manufactured by Tetrapak, is designed for high-speed application of plastic screw caps onto carton packages in industrial packaging and beverage production environments. The Cap 30 Speed model supports efficient cap application at up to 12,000 caps per hour, making it a reliable choice for a second hand or used bottling line where consistent throughput and precise cap placement are critical. It is well suited for integration into modern packaging machinery setups and can operate as part of a larger used bottling line for beverage production.

Engineered for accuracy and repeatability, the machine is compatible with Helicap 23 closures, commonly used in carton packaging applications. Its robust construction and proven Tetrapak engineering ensure stable performance for producers seeking to optimize industrial packaging efficiency without compromising quality. With testing available, this unit offers confidence in readiness and operational reliability.

Technical Specifications & Performance Data

- Manufacturer: Tetrapak

- Model: Cap 30 Speed

- Alternate reference: Cap30 Speed

- Year: 2012

- Production speed: up to 12,000 caps/hour

- Cap system: Helicap 23 (plastic screw cap)

- Cap size: 23mm

- Container type: Carton packages

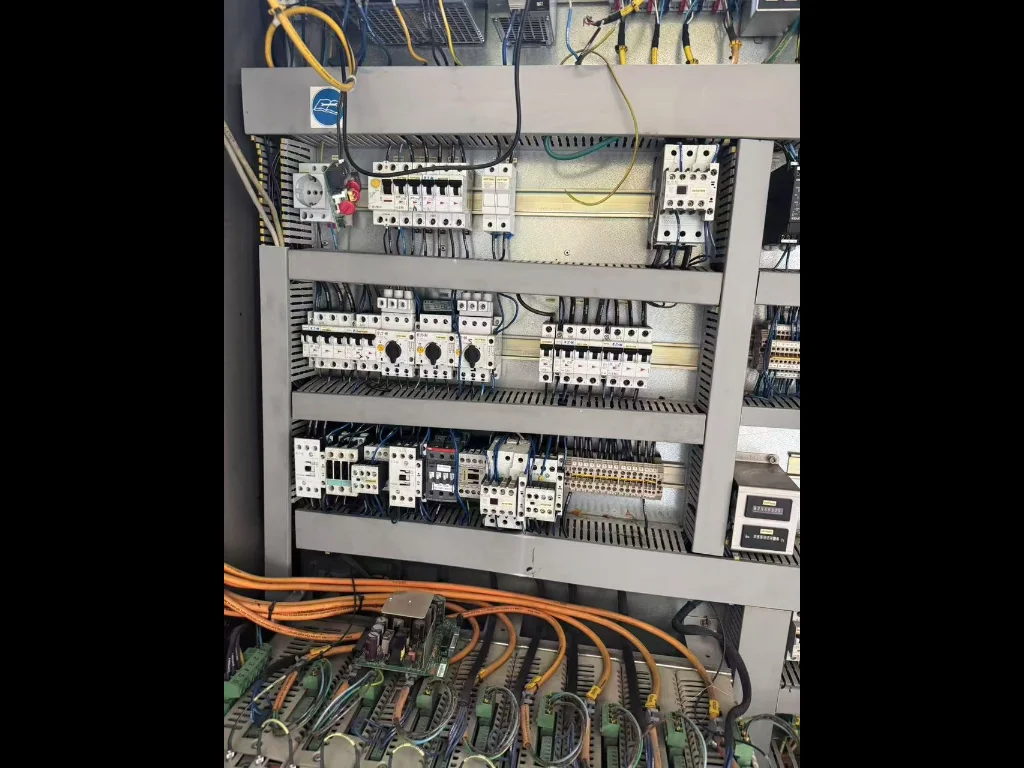

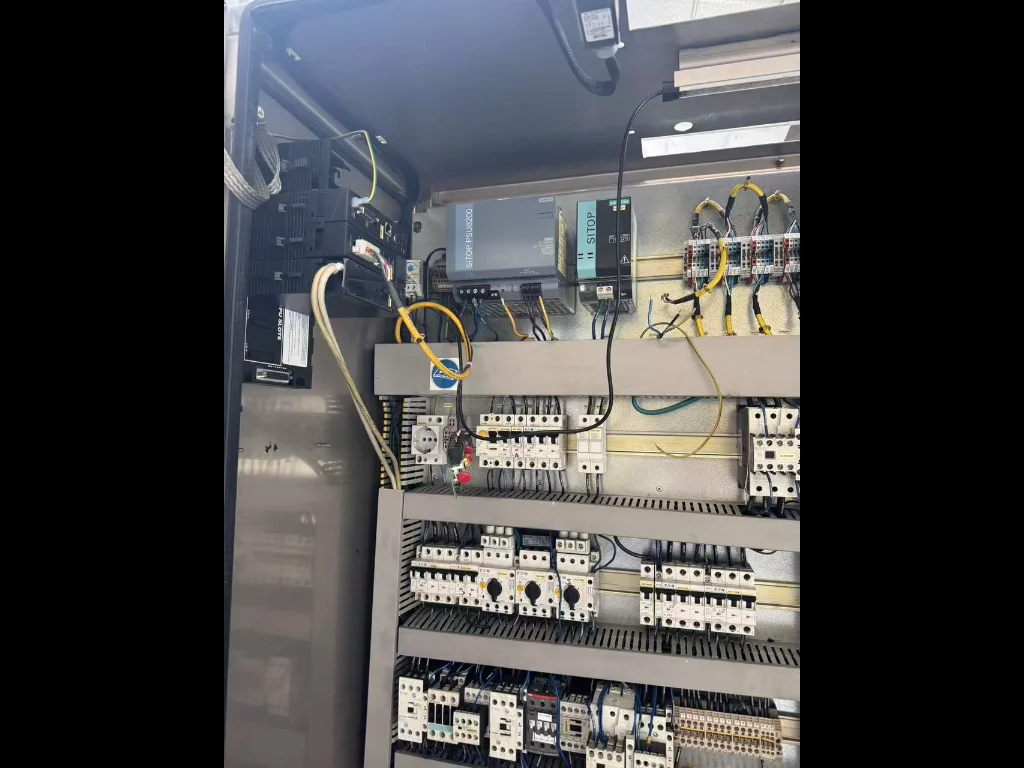

Advanced Automation & Control Systems

The Cap 30 Speed is built for dependable, automated operation within demanding production schedules. Typical features include an intuitive operator interface for quick setup and monitoring, integrated safety logic, and precise actuation for consistent cap positioning. Designed for high uptime, the machine supports streamlined changeovers and consistent application pressure, helping maintain output quality and reduce stoppages across extended shifts in beverage production.

Production Line Integration Capabilities

This cap applicator integrates efficiently into upstream and downstream equipment within a used bottling line or complete packaging system. It can be configured for inline operation with conveyors and synchronization signals for smooth product flow. The Helicap 23 compatibility supports widely used carton formats, making it a strong fit for industrial packaging lines that require dependable throughputs and minimal bottlenecks. Its footprint and connection points are suitable for common layout configurations, and it can operate as a standalone station or as part of a synchronized multi-machine line.

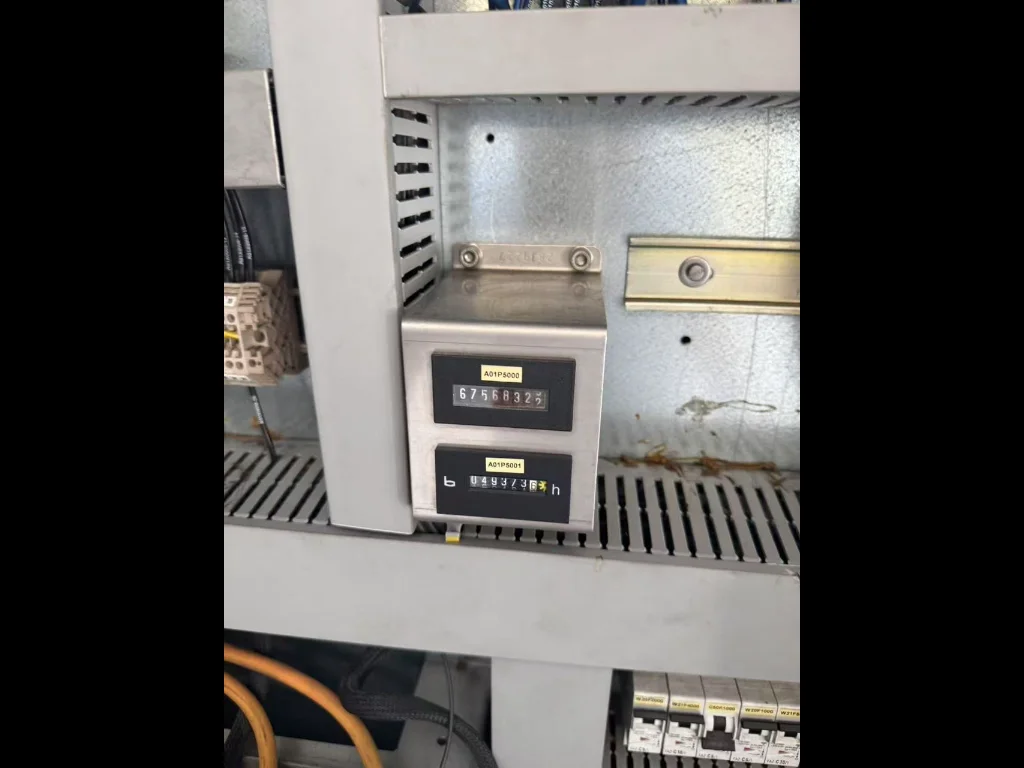

Machine Condition & Maintenance History

The applicator is available with the possibility to test the machine, indicating readiness for operation and providing assurance of functional performance. As a second hand solution, it represents a cost-effective option for facilities seeking dependable capping capability with verifiable operation prior to installation.

Operational Performance & Versatility

At 12,000 caps per hour, the machine delivers consistent performance for high-volume carton capping in beverage production. Helicap 23 compatibility ensures secure, repeatable application of plastic screw caps. Its stable mechanical design and precise application mechanism help maintain package integrity, reduce rejects, and support continuous operation in demanding industrial packaging environments.

Installation Requirements & Site Preparation

The machine is designed for integration into standard production layouts with conveyor interfaces. Typical site preparation includes adequate floor space for safe operator access, stable mounting, and provision for power and control interconnections with adjacent equipment. A clean, controlled environment helps maintain consistent application quality and long-term reliability.

Safety Standards & Compliance Certification

The Cap 30 Speed features protective guarding and emergency stop functions common to modern packaging machinery. Safety interlocks help prevent access to moving parts during operation. Its hygienic, easy-to-clean construction supports food and beverage industry requirements, aligning with the safety expectations for industrial packaging and used bottling line equipment.