Description

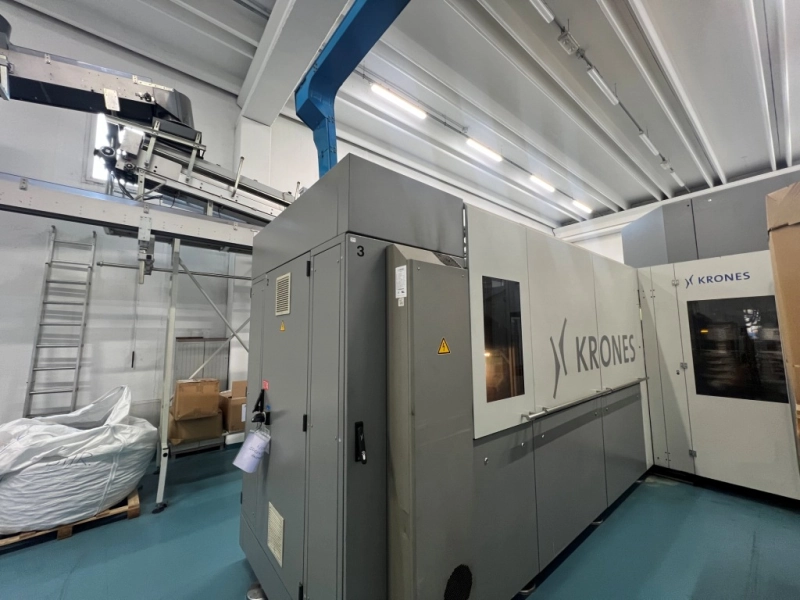

Used Blow Molding Machine Contiform

This used Krones Contiform S14 blow molding machine is engineered for high-output PET bottle production in modern beverage manufacturing. With a maximum speed of up to 25,000 bottles per hour, it is an excellent choice for businesses looking to expand capacity or upgrade a used bottling line with reliable second hand industrial packaging equipment. The machine is equipped with a Siemens PLC and a Krones HMI for robust automation and operator-friendly control. Neck-handling transfer ensures stable bottle handling across formats, while the rotary architecture delivers consistent performance for beverage production.

Manufactured by Krones, a global leader in beverage production technology, this model supports PET containers and is suitable for a wide range of products including still and sparkling water, soft drinks, milk, oil, beer, wine, and spirits. The current setup is optimized for 1.5L format and a maximum container height of 320 mm, making it a versatile asset for PET bottle processing in integrated bottling equipment lines.

Technical Specifications & Performance Data

- Manufacturer: Krones

- Model series: Contiform

- Model code: S14

- Year of manufacture: 2009

- Maximum speed: 25,000 bottles/hour

- Container material: PET

- Current format: 1.5L

- Maximum container height: 320 mm

- Worktable height: 1470 mm

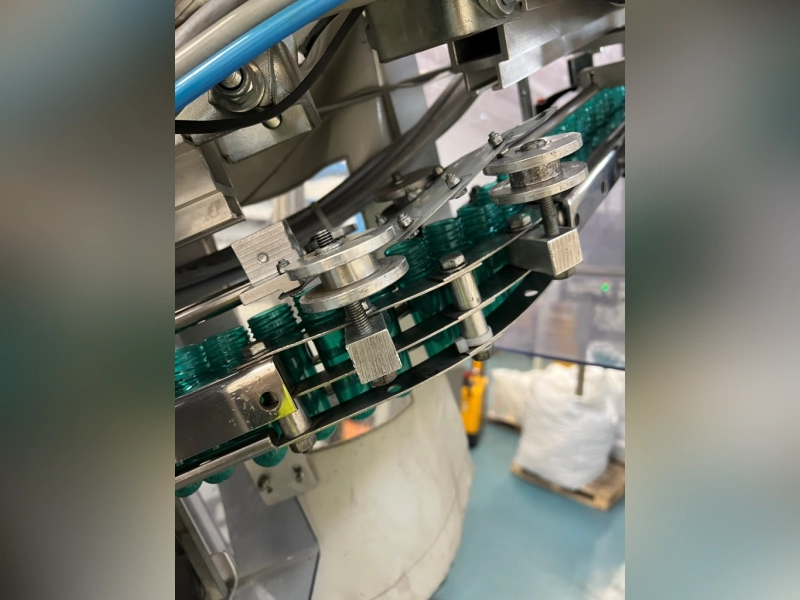

- Type: Rotary

- Transfer type: Neck-handling

- Neck finish: Alaska

- Number of cavities (molds): 14

- Number of spindles: 7

- Number of grippers (inlet/outlet): 7

- Work direction: Counterclockwise

- Electrical supply: 400 V, 3 PH + N, 50 Hz

- Rated current: 313 A

Advanced Automation & Control Systems

The machine features a Siemens PLC for reliable process control and a Krones HMI for intuitive operation, recipe management, and diagnostics. The electrical configuration at 400 V and 50 Hz with 3 PH + N supports stable, industrial-grade performance. Safety guarding and interlocked access points facilitate secure operation during production and changeovers. Neck-handling design contributes to smoother format adjustments and reduced container scuffing.

Production Line Integration Capabilities

This Krones Contiform S14 can operate as a standalone blow molder or be integrated into a complete beverage production line. It interfaces smoothly with preform handling systems, high- and low-pressure air utilities, and downstream conveyors leading to filling, labeling, and packaging machinery. The rotary platform and neck-handling transfer provide compatibility across typical PET bottle sizes, including 1.5L and other common formats used in water and soft drink applications.

Machine Condition & Maintenance History

The unit is available in multiple supply options: as-is (seen and liked), refurbished and guaranteed, or ready for operation with compatible spare parts. A 6-month warranty is available when supplied refurbished. These options provide flexibility to match project timelines and maintenance strategies.

Operational Performance & Versatility

Designed for PET bottle production, this blow molding machine supports a wide spectrum of beverage categories: still and sparkling water, soft drinks (CSD), milk, edible oil, beer, wine, and spirits. The Alaska neck finish configuration and neck-handling transfer optimize stability and quality during high-speed operation, contributing to consistent bottle quality in demanding industrial packaging environments.

Installation Requirements & Site Preparation

Plan for adequate floor space to accommodate rotary blow molder access and maintenance. Electrical utilities should supply 400 V, 3 PH + N, 50 Hz. A suitable compressed air system providing both high- and low-pressure circuits is required for PET stretch blow molding. Ensure appropriate ventilation and ambient conditions for stable preform heating and consistent bottle forming.

Safety Standards & Compliance Certification

The machine is equipped with physical guarding, interlocked doors, and emergency stop systems to support operator safety. Stainless steel and industrial-grade construction materials facilitate hygiene and durability in beverage production environments. Safety features and controls align with common industrial standards for bottling equipment.