Description

Technical Specifications & Performance Data

The Atlas Copco GA 250 Full-Feature is a water-cooled, oil-injected screw compressor engineered for continuous-duty industrial applications, including beverage production, industrial packaging, and integration into a used bottling line. This second hand compressor delivers reliable compressed air at the 10 bar class, providing stable performance for filling, labeling, capping, rinsing, blow molding, and auxiliary packaging machinery.

- Model: GA 250 Full-Feature

- Compressor type: Oil-injected screw, water-cooled

- Nominal operating pressure: 9.5 bar(e)

- Maximum operating pressure: 9.75 bar(e)

- Motor speed: 1,490 rpm

- Installed power (absorbed): 281 kW

- Cooling water flow (max): 5.6 L/s

- Oil capacity: 113 L

- Sound pressure level: 72 dB(A)

- Discharge temperature (water-cooled Full-Feature): approx. 22 °C

- Compressor element discharge temperature: 55–100 °C

- Pressure dew point (with integrated dryer): approx. 3 °C

- Electrical supply: 400 V, 50 Hz

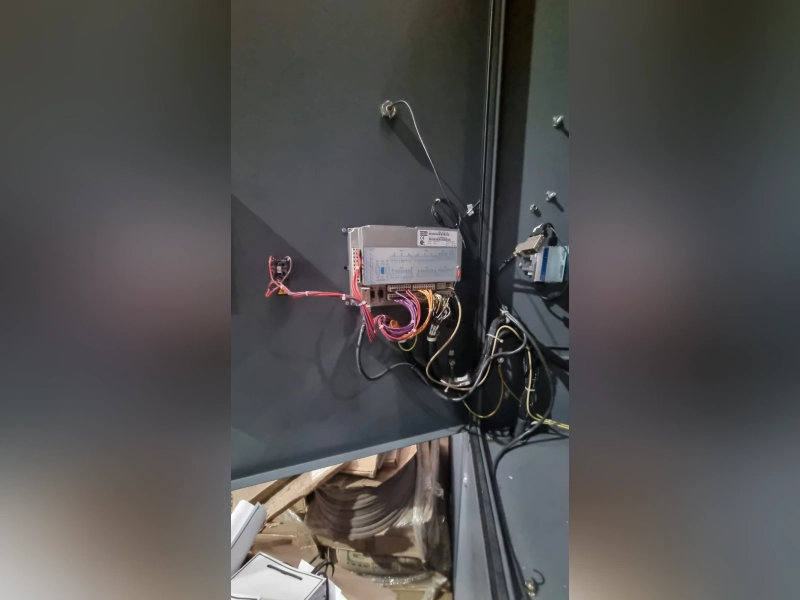

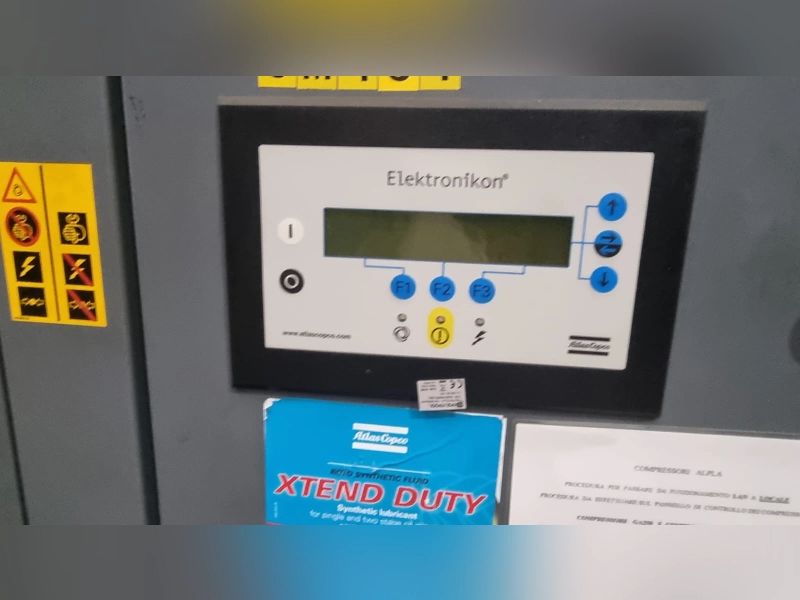

Advanced Automation & Control Systems

The integrated control interface displays the actual outlet air pressure and compressor status on the main screen. Operators can navigate to view additional live measurements, including pressures and temperatures throughout the system. Protective functions include coordinated overload relays and fusing for the main drive and auxiliary motors, along with defined circuit breaker settings for fan and dryer motors. The control system supports stable operation and straightforward diagnostics, ensuring consistent compressed air quality for beverage production.

- Operator HMI: Real-time outlet pressure and status

- Measured values: Filtration pressure drops, oil injection pressure, temperatures

- Electrical protections: Overload relays and fuses per component

- Safety: Safety valve settings aligned with pressure rating

Production Line Integration Capabilities

This compressor integrates seamlessly with a wide range of bottling equipment and industrial packaging machinery. It provides stable compressed air for PET blow molding, high-speed fillers, cappers, labellers, rinsers, and end-of-line systems. Its water-cooled design supports installation in environments where thermal management and noise control are critical.

- Suitable for standalone operation or inline utility support

- Supports beverage production equipment in PET and glass packaging lines

- Stable air supply for process actuators and pneumatic controls

Machine Condition & Maintenance History

Designed for continuous operation with robust industrial components. The Full-Feature configuration includes integrated drying for low dew point air to protect downstream bottling and packaging processes. Preventive maintenance practices are recommended to maintain performance and air quality.

Operational Performance & Versatility

With low sound emissions and precise thermal management, the GA 250 Full-Feature delivers clean, dry compressed air appropriate for beverage production environments. The integrated dryer achieves an approximate 3 °C pressure dew point, reducing moisture-related risks in valves, cylinders, and instrumentation used across a used bottling line. Temperature monitoring at discharge and at the compressor element provides operational transparency, while water cooling supports stable thermal control during peak demand.

- Noise performance: 72 dB(A) for improved operator comfort

- Dew point control: approx. 3 °C with integrated drying

- Thermal stability: Water-cooled design for consistent discharge temperature

Installation Requirements & Site Preparation

Set up the compressor in a ventilated technical area with adequate access for service. Provide a stable electrical supply and reliable cooling water circuit. Reference conditions for rated performance include 1 bar(a) inlet pressure, 20 °C inlet air temperature, and dry air.

- Electrical: 400 V, 50 Hz, 281 kW

- Cooling water: Flow up to 5.6 L/s; inlet water typically below 50 °C

- Ambient limits: 0 °C to 40 °C

- Compressed air system: Proper filtration, condensate management, and receiver sizing recommended

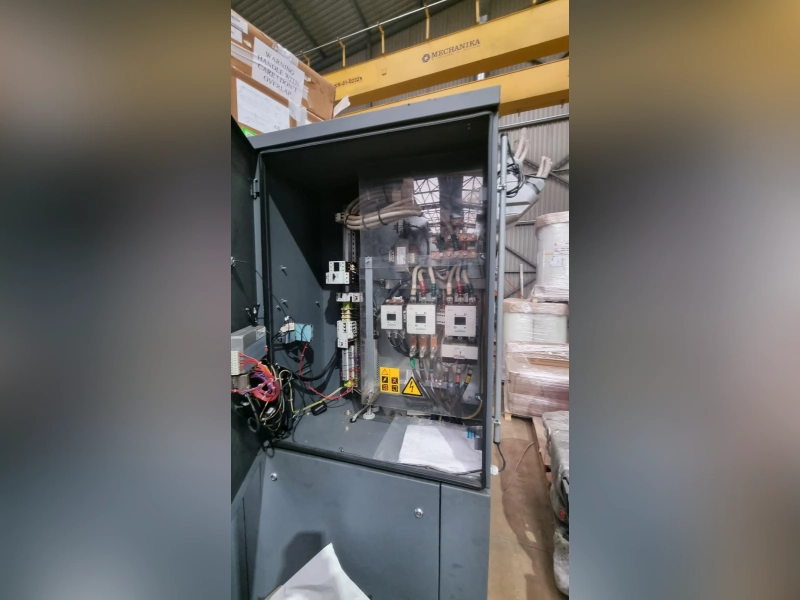

Safety Standards & Compliance Certification

The GA 250 Full-Feature incorporates comprehensive protective measures, including overload relays, appropriate fusing, and safety valve settings matched to the machine’s maximum operating pressure. Guarding and interlocks around moving parts and fans support operator safety. The integrated dryer and cooling system help maintain air quality and stable operating conditions for sensitive beverage and industrial packaging applications.

- Safety valve configuration according to pressure class

- Electrical protection devices for main and auxiliary drives

- Operator display for monitored pressures and temperatures

- Engineered for hygiene-critical environments supported by dry, clean compressed air