Description

Technical Specifications & Performance Data

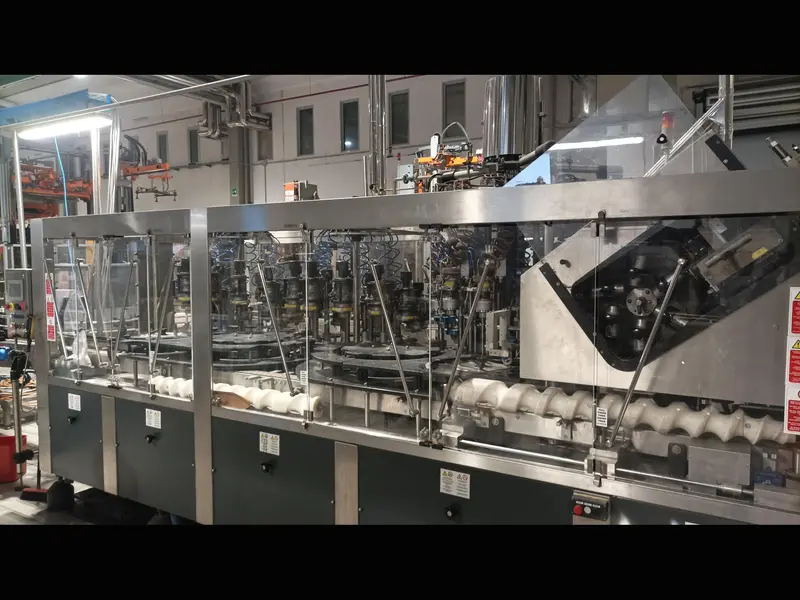

The Robino & Galandrino Minibloc is a compact capsuling machine engineered for precise capsule application in beverage production and industrial packaging environments. Designed for integration into a used bottling line or as a standalone unit, this second hand machine combines reliable mechanics with efficient operation for consistent results on glass bottles commonly used in wine and premium beverage applications.

- Manufacturer: Robino & Galandrino

- Model: Minibloc

- Year of manufacture: 2011

- Machine type: Capsuling machine

- Electrical supply: 400 V, three-phase

- Frequency: 50 Hz

- Input current: 1.2 A

- Frame concept: Compact miniblock layout for efficient floor space usage

Advanced Automation & Control Systems

Built to match modern beverage production requirements, the Minibloc supports dependable automation with straightforward operator controls. The three-phase 400 V, 50 Hz electrical setup ensures stable performance and compatibility with standard industrial power networks. Safety protections and operator-friendly adjustments help maintain productivity while reducing downtime.

- Operator controls engineered for practical, daily operation

- Electrical system: 400 V 3-phase, 50 Hz

- Safety interlocks and guards for protected operation

- Mechanical quick adjustments to support format changes

Production Line Integration Capabilities

This capsuling machine integrates seamlessly after cappers, corkers, wirehooders, or labelers within a bottling line. Its compact frame is well suited to retrofits in existing packaging machinery layouts and to diversified beverage production scenarios.

- Inline or standalone operation within a used bottling line

- Compatible with conveyors and standard line controls

- Format adjustments for varying bottle heights and diameters

- Ideal for integration in wine and premium beverage packaging

Machine Condition & Maintenance History

The 2011 Robino & Galandrino Minibloc is presented as a professionally maintained second hand capsuling solution suitable for immediate inclusion in beverage production and industrial packaging processes. It offers a dependable build quality typical of Robino & Galandrino engineering.

- Condition aligned with ready-for-operation expectations

- Robust construction supports long service life

Operational Performance & Versatility

Engineered for consistent capsule application, the Minibloc supports smooth feeding and stable spinning for a clean, uniform finish around the bottle neck. It is commonly configured for PVC shrinkable plastic capsules and polylaminate aluminum capsules used in still wine, fortified wine, and premium beverages.

- Precise capsule placement and secure finish

- Configurable for different capsule materials and bottle designs

- Stable mechanics designed for continuous-duty operation

Installation Requirements & Site Preparation

Site preparation is straightforward thanks to its compact footprint and standard utilities. Ensure suitable electrical service and line alignment to upstream and downstream equipment for smooth product flow.

- Electrical requirements: 400 V (3F), 50 Hz, approx. 1.2 A

- Compact layout simplifies positioning and integration

- Level, clean, and accessible installation area recommended

Safety Standards & Compliance Certification

The Minibloc incorporates protective guards and emergency stop functions appropriate for beverage packaging environments. Hygienic design and cleanable surfaces support quality standards in bottling operations.

- Mechanical safety guards and emergency stop circuitry

- Design suitable for food and beverage packaging environments

- Sturdy construction aligned with industrial safety practices