Description

Used Frozen Orange Processing Line

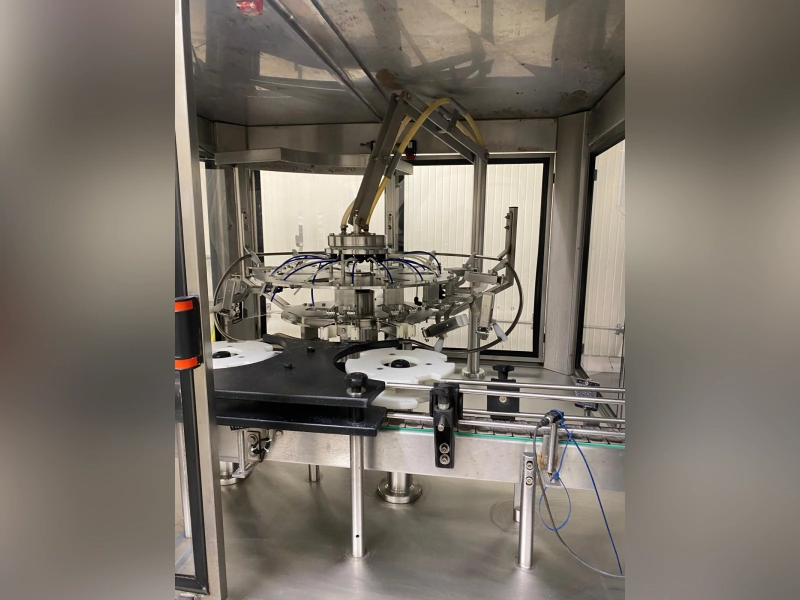

The Frozen Orange Processing Line by Navatta Group is an industrial processing solution engineered for handling frozen citrus products with high reliability and safety. Built in 2011 and configured under model QE11056, this second hand line is suitable for integration within beverage production and industrial packaging environments where pre-processing of fruit inputs is required. Designed for continuous-duty operation, it provides robust automation, comprehensive operator protections, and compliance with stringent European safety standards. Its electrical and control architecture supports stable performance and straightforward integration into a complete used bottling line or broader food and beverage processing workflow.

Manufactured by Navatta Group engineering, the line is tailored for frozen orange processing applications, with the flexibility to interface with downstream equipment such as filling, labeling, capping, and packaging machines. It is an optimal choice for producers seeking dependable performance in industrial packaging contexts, enabling efficient preparation of fruit-based inputs for further transformation within beverage production lines.

Technical Specifications & Performance Data

- Manufacturer: Navatta Group

- Model: QE11056

- Year: 2011

- Primary voltage: 400 V

- Auxiliary voltage: 24 V

- Frequency: 50 Hz

- Installed power (absorbed): 47 kW

- Maximum current: 93.1 A

- Short-circuit current rating (Icc): 40 kA

- Line type: Frozen orange processing line

Advanced Automation & Control Systems

The line features a dedicated electrical panel with clearly identified electrical characteristics and operator controls. Automation is supported by integrated control and safety logic designed to minimize risk and streamline operation. The system provides:

- Operator control panel with descriptive indicators and alarms

- Structured safety devices and interlocks for guarded operation

- 24 V auxiliary control circuits for reliable low-voltage signaling

- Industrial-grade electrical build complying with EN 60204-1

- Designed for quick parameter adjustments during format or process changes

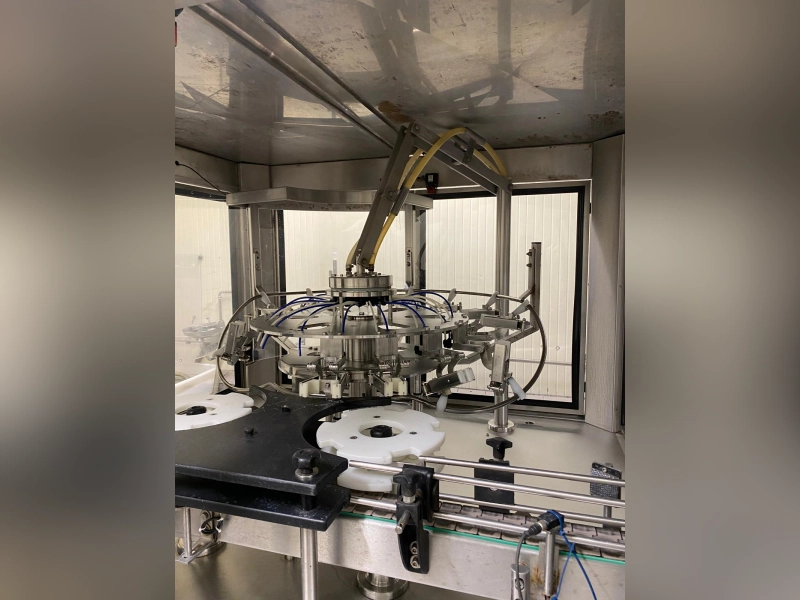

Production Line Integration Capabilities

This line is engineered to be positioned inline with upstream and downstream equipment. It can operate as part of a broader used bottling line or food processing cell, supporting material handling and transfer to filling, labeling, capping, and packaging stations. Integration features include:

- Inline positioning with conveyor and utility connection readiness

- Compatibility with industrial packaging workflows

- Process parameters adjustable for product handling requirements

- Suitable as a pre-processing stage in beverage production environments

Machine Condition & Maintenance History

The equipment is supported by a comprehensive user and maintenance manual, including electrical schematics and functional specifications. Standard maintenance procedures cover washing, lubrication, and scheduled checks as part of a preventive maintenance plan. Documentation supports efficient recommissioning and sustained operation.

Operational Performance & Versatility

Optimized for frozen orange processing, the line provides stable handling, controlled operation, and safety-focused design. It is appropriate for facilities seeking to process fruit inputs prior to liquid filling stages, providing a dependable bridge between raw material preparation and subsequent industrial packaging steps.

- Consistent processing for frozen citrus inputs

- Robust build for continuous industrial duty

- Scalable integration with downstream packaging and bottling equipment

Installation Requirements & Site Preparation

Installation guidelines cover transport, handling, storage, and mounting within a production line. Utility requirements are centered around the electrical supply and control voltages detailed in the specifications.

- Electrical supply: 400 V, 50 Hz, with 24 V auxiliary circuits

- Installed power: 47 kW

- Provision for safe lifting and machine positioning

- Clearances for operator access and maintenance

Safety Standards & Compliance Certification

The line conforms to European directives and harmonized standards for machinery, electrical safety, and electromagnetic compatibility. Safety features include guarded areas, emergency stop systems, and clearly defined operator procedures.

- Machinery Directive 2006/42/EC

- Low Voltage Directive 73/23/EEC

- Electromagnetic Compatibility 89/336/EEC, 92/31/EEC

- Standards: EN 12100-1/2, EN 294, EN 349, EN 418, EN 811, EN 953, EN 1005, EN 563, EN 60335-2-41, EN 60204-1

- Structured safety devices and CE marking