Description

Used Kosme Monocombi 2T Hot Melt Case Packing Monoblock

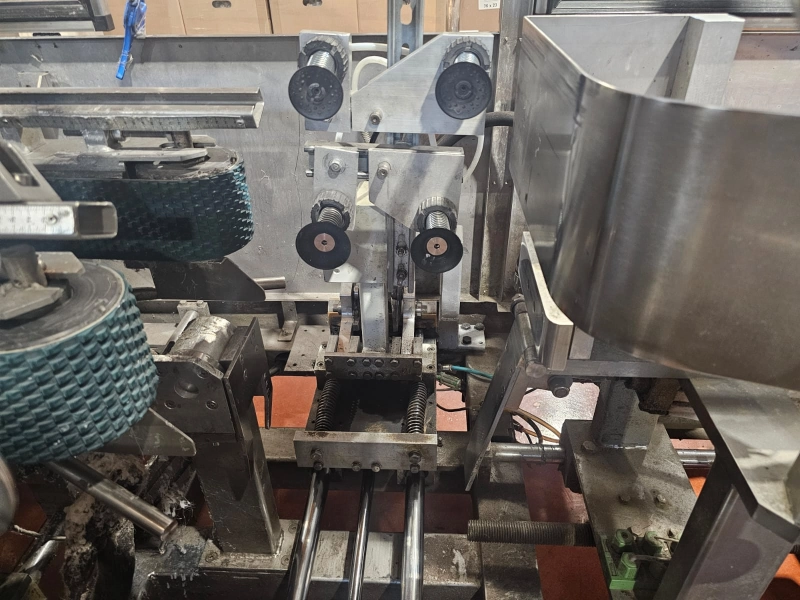

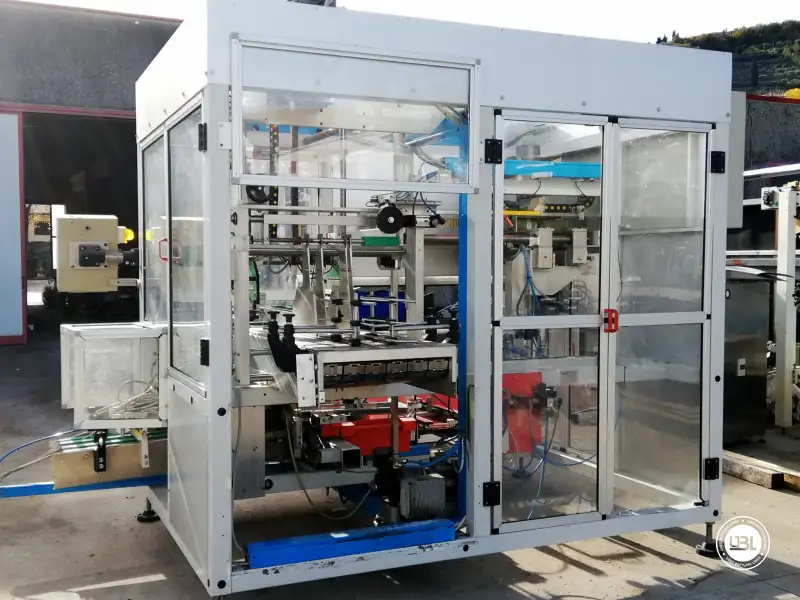

This second hand Kosme casepacking monoblock is designed for reliable bottle grouping and carton closing within a compact industrial packaging footprint. Built to support demanding beverage production environments and other bottling applications, it handles bottle collation into 6-bottle cartons and applies hot melt closure in a single integrated unit. Its monoblock architecture reduces footprint, simplifies integration on a used bottling line, and streamlines operation and maintenance.

Manufactured by Kosme, a recognized brand in bottling and packaging machinery, this model features an additional bottle centering device tailored for Authentique bottle handling, improving infeed stability and pack quality. Suited to both PET and glass bottles, it aligns well with beverage production requirements where consistent case presentation, secure hot melt sealing, and repeatable format results are essential. With a practical power rating of 8 kW and manuals available, the machine supports efficient commissioning and routine upkeep for continued performance in industrial packaging operations.

Technical Specifications & Performance Data

- Manufacturer: Kosme

- Model: Monocombi 2T

- Year of manufacture: 2007

- Machine category: Casepacking Monoblock

- Pack format: 6-bottle cartons

- Closure system: Hot melt

- Power: 8 kW

- Container handling: PET and Glass bottles

- Included device: Additional bottle centering for Authentique bottle

- Documentation: Operating and maintenance manuals available

Advanced Automation & Control Systems

The monoblock layout integrates bottle collation, case loading, and hot melt closing for streamlined automation. Operator-friendly controls support quick setup and routine adjustments. The hot melt gluing system ensures consistent sealing quality with minimal operator intervention, improving uptime and minimizing rework in continuous production.

Production Line Integration Capabilities

Engineered for straightforward integration into a used bottling line or as a standalone casepacking station, the machine interfaces with upstream conveyors and downstream palletizing solutions. Its compact monoblock footprint helps optimize floor space while maintaining access for changeovers and maintenance. The 6-bottle carton configuration fits common beverage logistics standards and can be combined with typical secondary packaging flows in beverage production.

Machine Condition & Maintenance History

Offered as second hand industrial packaging equipment, this machine comes with operating and maintenance manuals, facilitating proper setup and care. The presence of manuals supports efficient maintenance routines and helps sustain long-term reliability on the production floor.

Operational Performance & Versatility

Designed to handle both PET and glass bottles, the machine is suitable for beverage plants looking for dependable case formation and hot melt sealing. The additional centering device for Authentique bottle enhances stability at infeed and improves grouping accuracy before loading into cartons, contributing to consistent pack presentation and reduced stoppages.

Installation Requirements & Site Preparation

With an installed power of 8 kW, the casepacking monoblock is suitable for standard industrial utilities. The compact monoblock design eases positioning within existing layouts, and typical connections for conveyors and hot melt systems enable rapid commissioning within an established production line.

Safety Standards & Compliance Certification

The machine incorporates typical safety guarding and emergency stop features expected in modern packaging machinery, supporting safe operation during continuous shifts. Enclosures and interlocks help protect operators during routine production, adjustments, and cleaning activities, aligning with good practices for food and beverage packaging environments.