Description

SACMI OPP Roll-fed Labeling Machine – Overview

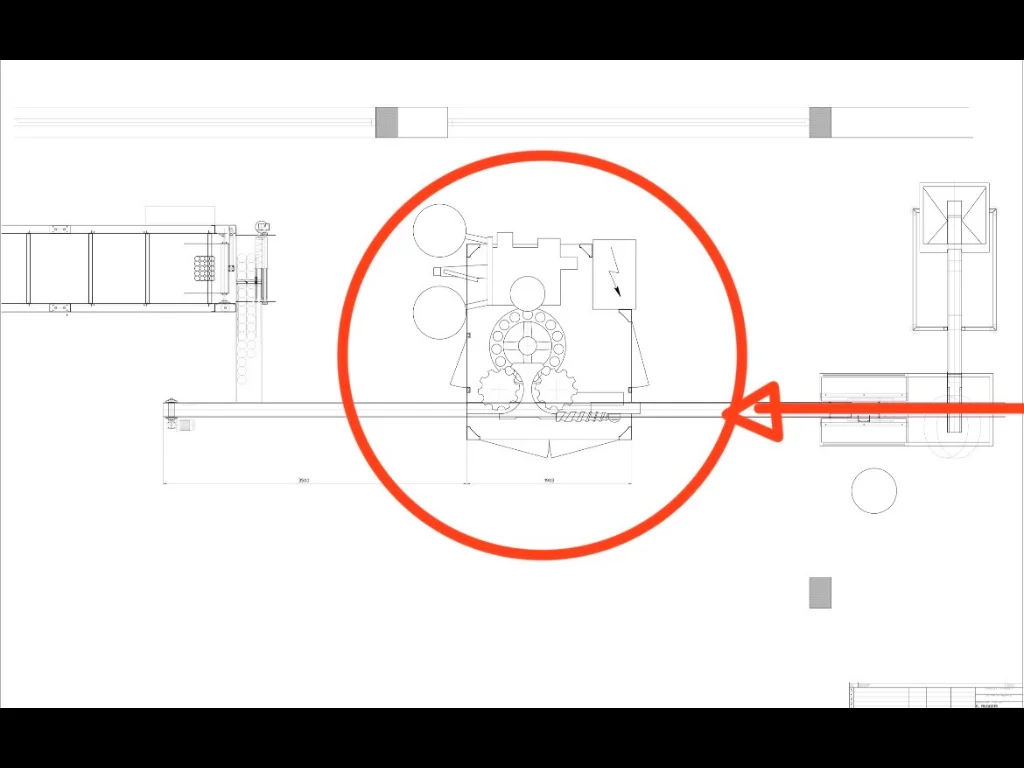

This used SACMI OPP roll-fed labeling machine is configured for high-efficiency wrap-around label application on PET bottles. Built in 2008 and designed for modern beverage production, it integrates seamlessly into a used bottling line or can operate as a standalone station within industrial packaging environments. With a nominal capacity of 12,000 bottles per hour, it is well suited for medium-speed operations in water, juice, and other beverage segments that use OPP film labels. SACMI engineering is known for durability, precision, and reliability, making this second hand labeling solution a strong fit for producers seeking dependable bottling equipment.

The machine supports multiple PET bottle formats, including 1.5L, 0.6L, and 0.33L sizes, providing flexibility for varied SKUs and seasonal product runs. OPP film labels, applied as roll-fed wrap-around, help reduce labeling costs and improve presentation quality with clean seams and consistent label placement. This configuration is a practical choice for beverage production facilities looking to upgrade or expand capacity while maintaining a compact footprint and streamlined integration into existing conveyors and handling systems.

Technical Specifications & Performance Data

- Manufacturer: SACMI

- Year: 2008

- Label type: OPP foil (roll-fed)

- Production speed: 12,000 bph (nominal)

- Bottle formats: 1.5L, 0.6L, 0.33L

- Container material: PET

Advanced Automation & Control Systems

The OPP roll-fed concept leverages hot-melt application at the leading and trailing edges of the label for secure wrap-around results. The design supports stable bottle handling, precise label feed, and consistent cutting for high-quality presentation. Controls are straightforward for operators, with clear access to key adjustments and process parameters to support quick setup and format changes.

Production Line Integration Capabilities

This labeling machine integrates easily into complete bottling lines and industrial packaging systems. It can operate inline with upstream filling and downstream inspection, packing, or shrink wrapping equipment. Format changeovers accommodate common PET bottle sizes such as 0.33L, 0.6L, and 1.5L, allowing multi-product flexibility across beverage portfolios within a single production line.

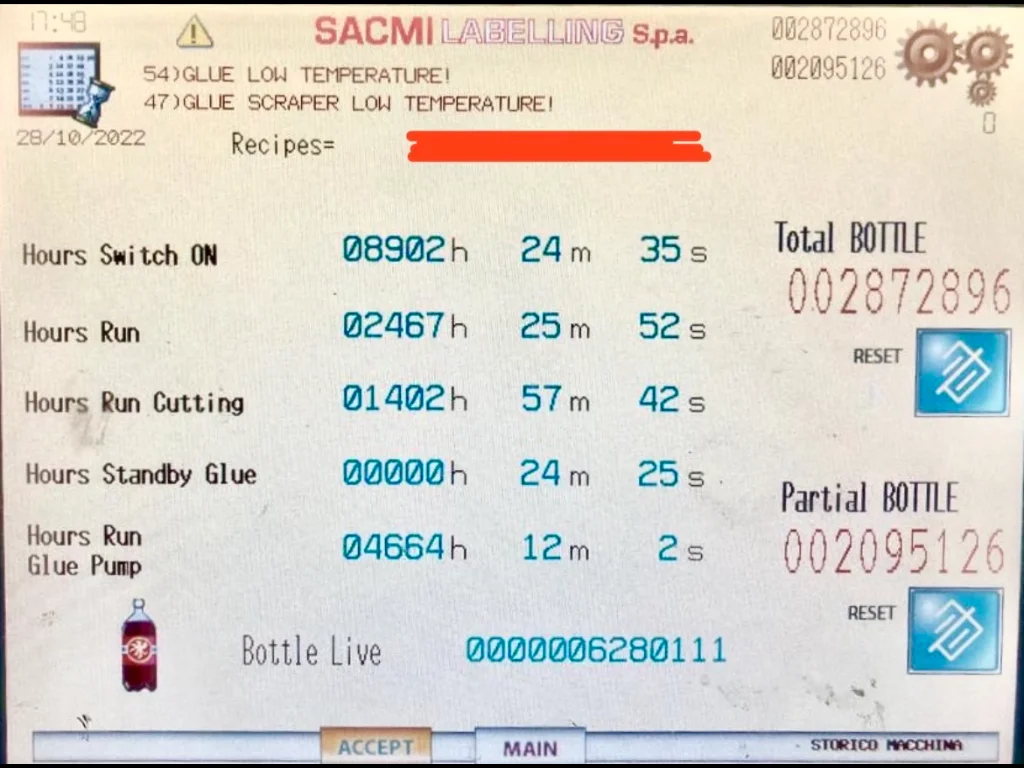

Machine Condition & Maintenance History

The unit has approximately 10,000 working hours. It is currently disconnected from the line but can be powered to demonstrate bottle transport. The machine can start and run, with label gluing disabled for demonstration purposes. Technical documentation is available, supporting commissioning, operation, and maintenance. Overall, the machine presents as a well-kept second hand asset suitable for facilities seeking reliable labeling performance at medium speeds.

Operational Performance & Versatility

Optimized for PET bottle labeling with OPP film, the machine delivers consistent wrap-around application across multiple formats. It is suitable for beverage production scenarios where high presentation quality and material efficiency are important. The roll-fed approach offers a cost-effective alternative to pre-cut labels while maintaining robust adhesion and label alignment at speed.

Installation Requirements & Site Preparation

The compact rotary layout supports straightforward placement in existing lines. Users should allow sufficient space for infeed and outfeed conveyors, operator access, and routine maintenance. Standard plant utilities are required for power and glue system operation. Site preparation should include alignment with upstream and downstream conveyor elevations and provisions for safe operator access.

Safety Standards & Compliance Certification

The machine is equipped with standard industrial safety guarding and emergency stop functions appropriate for labeling operations in beverage packaging. Materials and design support hygienic operation for food and beverage environments, with accessible areas for cleaning and maintenance in accordance with typical industry practices.